Position sensing in contemporary engineering is revolutionized by the absolute encoder, which is a precise device. These advanced gadgets offer precise, real-time position data without requiring movement or a reference point. An absolute encoder provides unmatched dependability in crucial applications by preserving position data even in the event of a power outage, in contrast to their incremental equivalents. They are essential in robotics, aircraft, and industrial automation, where precise motion control is crucial, because of their capacity to provide distinct position values.

Absolute encoders are widely used in servo motors, CNC machines, and even renewable energy systems due to their accuracy and durability. The three main types of absolute encoders:

Optical Absolute Encoder –

It uses light transmission through a coded disc to determine position. It offers high precision and is widely used in industrial applications.

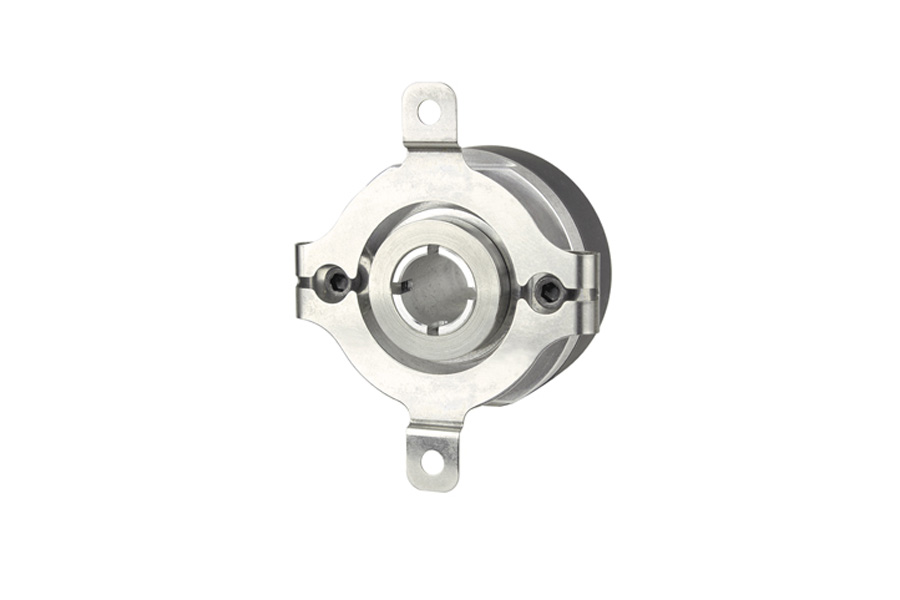

Magnetic Absolute Encoder –

Utilizing a magnetized disc and Hall-effect sensors, the encoder is robust and resistant to contamination, making it suitable for harsh environments.

Capacitive Absolute Encoder –

It uses changes in capacitance to determine position. It is less common but offers advantages in certain applications due to its resistance to electromagnetic interference.

Accuracy and resolution

The number of distinct positions, graduations, or slots that can be encoded—usually represented in bits—determines resolution in absolute encoders. Conversely, the degree to which the reported location closely resembles the real physical position is known as the absolute encoder’s accuracy. It is affected by things like the quality of the signal-processing circuitry, the alignment of optical components, and the accuracy of disc manufacturing.

Fast data transfer

Fast-bandwidth connections and sophisticated communication protocols are used to transmit data at fast speeds. Higher effective data rates are now possible without raising the raw bandwidth needs thanks to some encoders’ on-board processing capabilities, which enable real-time error correction and data compression.

Motion control is revolutionized by the absolute encoder, which delivers instantaneous, precise location data without homing. Numerous applications make use of their adaptable, high-resolution designs. Their applicability is increased by sophisticated features like communication protocols and multi-turn capability. These encoders are essential as companies strive for accuracy in automation. Their capabilities will be further improved by the next developments in AI and materials, guaranteeing location sensing’s continued precision and dependability.